Milling machines 5 axes

Introduction

The choice of a machine 5 axes depends largely on the configuration of the axes. For each type of machine one finds a type of part. The first consideration has to take into account in the choice of the machine is of course the workpiece. Its size, its geometry, its weight as well as the materials to be machined is the first criteria for the choice of a machine. The number of parts as well as the forms to be machined have also their importances. A machine whose rotary axes are located on the head for example will be less recommended if one wants a large flow chip and this particularly if one machines materials are hard. In this case the existence of a hydraulic lock of the axes will have importance in the choice of the machine. In the same way a machine with plates is not desirable for very heavy or very bulky parts.It is clear that first experiment of machining 5 axes is necessary to include/understand the possible limitations as well as the advantages of a standard configuration of a 5 5 Axes machine.

Recall on conventions

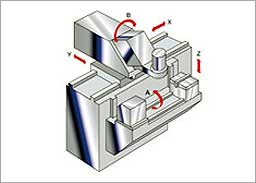

Generally a milling machine consists of linear axes that ensure a displacement in the volume of work following 3 directions: X Y and Z.One can occasionnly have a fourth linear axis that ensures a surlonguor of work or which allows an access to the zones to be machined through the part. This axis is coded with the letter W.

The axes of orientation in space are generally rotary axes. One needs

two axes to direct our tool in all the positions of space.

The convention most often used in the manufacturers is as follows:

the axes are called A/B or C: With for a revolving axis around X, B around

Y and C around Z.

Type of machine

You will find four main types of machine:Machines with head twist (2 rotary axes with 90 degrees on the head)

Machines with universal head (2 rotary axes with 45 degrees on the

head)

Machines with plate tilting (2 rotary axes on the table of the machine)

The machines with an axis on the head and a rotary table (generally

the plate is an axis C).

Machines with head twist

These gantry machines generally, are often large-sized machines. One finds them in aeronautics or the car industry, they make it possible to mill large-sized parts. the movements 5 axes on this type of machine are not influenced by the weight of the part, because here only the tools are moving.

TETE B/C |

Doc.:Forest-line |

These machines generally have an axis A limited to +-110°/120° and

an axis C which can be unlimited but unfortunately with all the new options,

wiring and others which must pass in the head have finds now much more

head limited with values of + - 400° to see +-200° or even +-110°.

Note: a machine limited on its axis C with values of +-110° must ABSOLUTELY be avoided for 5 continuous axes indeed how to machine a part if one cannot even make the turn of a part (360°) in one only passes. |

Horizontal TETE B/C |

Doc.:Forest-line |

The horizontal head allows better an evacuation of the chip. These machines are thus reserved for applications with much removal of matter (Typically aeronautics) |

ASYMMETRICAL TETE A/C |

Doc.:Breton |

Idem with the preceding configurations, the Twists heads can exist in symmetrical configuration or Assymetrique. A assymetric head loses a little in rigidity but makes it possible in certain cases to manage, while turning the head of 180° of the problems of collisions. |

Universal TETE B/C |

Doc.:Mecof |

These configurations with these axes with 45° make it possible to

limit the quantity of displacement of the point pivot in the movements

5 axes. The machine is thus more "swift" in 5 axes continues, but these

machines are much difficult to manage by the operator and moreover by construction

a limit imposes on 90° of the position pièce/machine.

Note: for example if you wish to carry out a machining with 45° the values of the axes to be given are: B=59.94° C=249.66° the programming manual is thus very difficult without a table of equivalence. There exists however on certain order-numerical (840D for example) of the functions making it possible to make programming in "true" angles the machine will convert automatically into angle machine. |

Machines with universal head

I call universal head of the machines whose 2 axes are located on the head and are convergent; one of the axes is with 45° compared to the other.

Universal TETE A/B |

Doc.:Mecof |

This type of kinematics is seldom taken into account in the software

of CFAO, the axis tool is often axis X whereas the axis safe Outil for

software to my knowledge is always axis Z also must one rely on the post-processor

to control this type of machine in 5 axes.

Moreover the horizontal slide in this case of figure, a capacity of machining imposes limited on 4 faces (inaccessible face back) what limits the advantage of these machines for 5 pure axes. In certain case the slide obliges even with a use on 2 faces. One can thus ask for in this case the interest of these machines for a use "5 axes". |

Machines with plate tilting

This configuration of machine 5 axes with vertical pin and table Bi-rotary printing-press AC. This kinematics does not have an influence in 5 axes on the relative position outil/pièce according to lengths' tools. Only the position of the part compared to the origin machine will have to be taken into account for the calculation of the trajectories tools.

PLATE A/C |

Doc.:Hermle |

This configuration is frequently used in energy industry (Machining

of turbine) because it makes it possible to obtain an axis C unbounded

and an axis A with a great angular variation (+ - 120°).

Doc.:Breton |

PLATE A/C A 45° |

Doc.:Huron |

This configuration is not very frequent (HURON, DECKEL). The angles

with 45° make it possible to limit the quantity of displacement by the

machine ,is thus more "swift" in 5 axes continues, but they are much more

difficult to manage by the operator (analyzes movements, programming manual)

and moreover they impose by construction a limit on 90° of the position

pièce/machine.

Note: Here the position of the plate makes more difficult the loading of the parts for me this machine is to be held for applications 5 continuous axes exclusively. |

Machines with an axis on the head and a rotary table

A solution often adopted in the manufacture of tools and forms like for the manufacture of unit parts and parts manufactured in small series. The management of the trajectories is more difficult indeed compared to a course calculated in FAO, on the machine the position part machine, as well as the lengths of tools have an influence on the finale result.

TETE B PLATE C |

Doc.:Hermle |

This configuration allows as for the configurations plates to have

an axis C unbounded but attention often the axis B is limited to

values of -10, -5° +90, +110° what with the use for 5 continuous axes

is very handicapping.

Note:ce standard machine is particularly adapted for parts "cylindrical" (part requiring to carry out machinings while turning around the part). |

TETE B has 45° PLATE C |

Doc.:DMG |

Unlimited plate, but from its construction head limited to the horizontal one. |

TETE B STITCHES A |

Doc.:liechti |

Typical machine for machinings 5 Axes of the Turbine blades type. |

TETE B has 45° PIN A |

Doc.:starrag |

Machine specialized for machinings 5 Axes of the Turbine blades type. |

TETE A PLATE C |

Doc.:starrag |

This configuration of machine is a good solution for parts of the energy type, turbine blades, turbines (machining around the part but little machining "by the top" because of the slide horizontal). |

New architectures

New architectures of machine appear on the market. For these machines the rotary axes which made it possible to direct our tools in space are replaced by linear axes. These machines are according to the specialists more rigid than traditional machines and are more dynamic. However they are more cumbersome, the capacities of orientation of the tools are reduced and their piloting and adjustments are difficult. The limits of machining in 5 axes still imposes the addition of rotary tables for stage on these limitations.

Hexapode Machine |

Doc.:CMW |

This rigid architecture, makes it possible to obtain a great chips volume for large-sized parts. However the angles of inclination of the tool are limited enough. One will thus not be astonished to find these machines as they exist only in the aircraft industry. Where, they find their place in the machining of elements of structure. |

TRIPOD |

Doc.:starrag |

Machines 4 axes with its rotary table and structures parrallel Tripode.: |

TRICEPT |

Doc.:smt-tricept |

Tripod machine with 2 rotary axes |

5 axes with the range of the amateurs

The last small link on the site of a petiite undertaken Ecossaise which shows that:

Please send your comments, bug carryforwards and others to: mailto:usinage5axes@free.fr

|

|